04 Nov Stellio Heliostat confirms unprecedented optical and economic performance

Point-focusing Solar Energy Technology

The Stellio Consortium obtained formal recognition for what is known to be the best-in-class heliostat technology internationally available. CIEMAT-PSA – Unidad de Sistemas Solares de Concentración, and CSP Services independently evaluated the Stellio heliostat technology performance. The results confirmed optical quality close to theoretical limits and excellent tracking quality, which is a major step in achieving a minimized Levelised Cost of Energy (LCoE).

The engineering design study optimized the prototype to site conditions which were initially elaborated for and in collaboration with the South African company SASOL Technology, for the South African market.

sbp sonne gmbh formed a consortium with Masermic, and Ingemetal Solar to proceed with the 1.5-year-long techno-economic study.

It analyzed and benchmarked all existing technologies and their cost structures, which resulted in the optimized design of the Stellio heliostat. The specific cost close to 100 Euro/m² will be achievable at an overall beam quality that can be closely examined at the tested values table below. The LCoE will be reduced by over 20 percent (15 percent heliostat cost reduction and five percent reflective area due to higher efficiency) compared to today’s most competitive heliostat design.

| Concentrator new reflective area | 47.5m² |

| Concentrator slope deviaton (based on deflectometry measurement) |

0.9 mrad/0.87mrad (rms in x / rms in y – direction) 1.18 mrad in both direction daily average (using beal characterization system ProHermes 2.A) |

| Tracking quality (1 s standard deviation) | <0.4 mrad / <0.6 mrad (minimum axis / maximum axis) |

| Power Consumption | 15W / 180W (average / maximum) |

Stellio technical data and tested performance values (© schlaich bergermann partner)

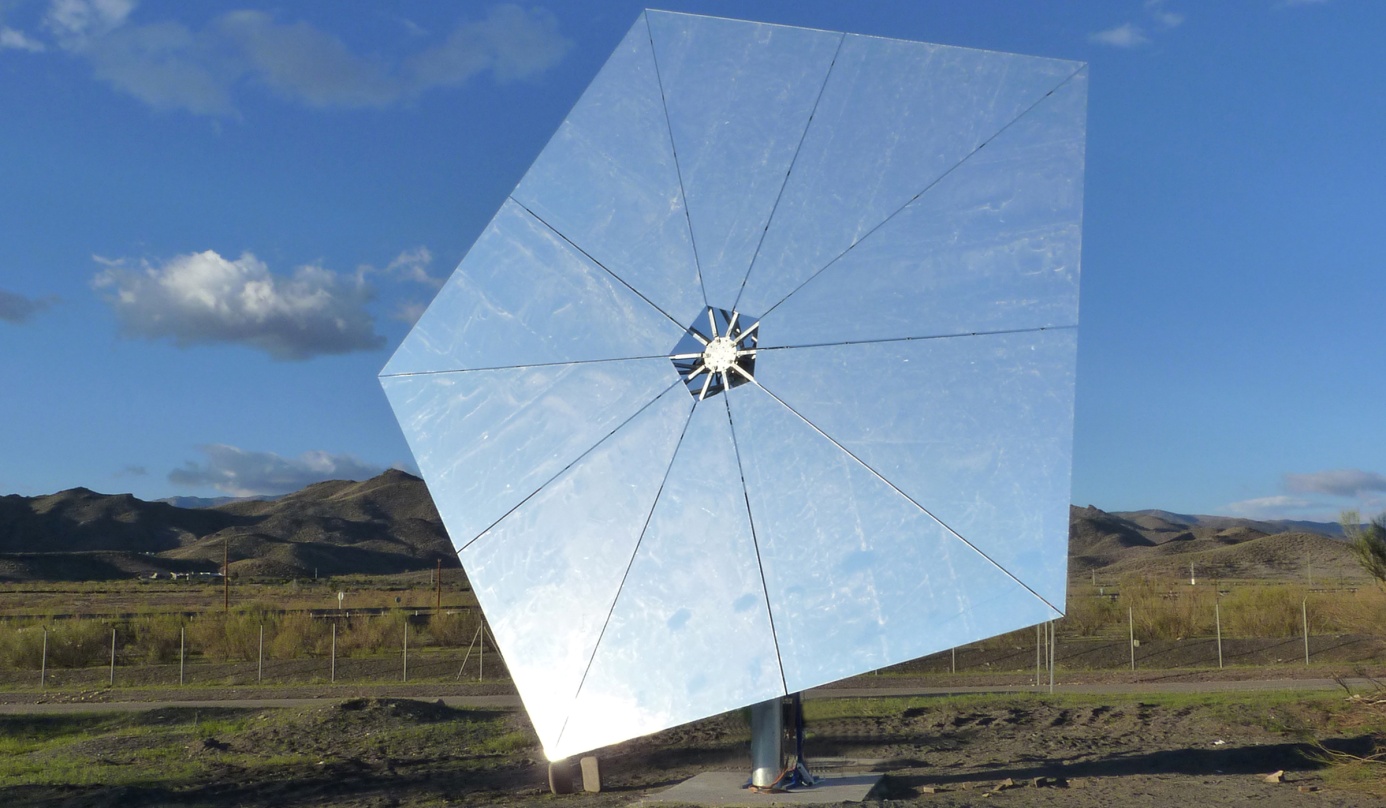

Design Stellio heliostat technology

The superior beam quality is achieved through “equal stiffness” of its concentrator support system and a clever assembling method developed for high production numbers. The high optical performance derives from an assembling concept that allows comparatively large steelwork tolerances; the mirror support system contains a highly precise connection with the mirror-steel structure, limiting the quantities of support positions and optimizing the accuracy of the mirrors.

The linear actuators for both axes in the drive system minimize procurement and maintenance costs, and the design of a special axes arrangement allows the use of cost-efficient modified linear actuators with off-the-shelf equipment. A simple configuration of the drive mechanism can self-calibrate using intelligent software that compensates tolerances, self-weight deflections and/or foundation behavior. The control and drive systems of the Stellio heliostat redefine control strategies for heliostats, simultaneously enabling the highest tracking accuracy and minimization on structural CapEx (Capital Expenditure).

The Stellio heliostat is offered as a turn-key system by the Stellio Group Partners comprising schlaich bergermann partner – sbp sonne gmbh, Ingemetal and Masermic. The group has a combined extensive know-how based on over forty years of international experience in all existing CSP technologies and over 600 operating MW of Concentrated Solar Power (CSP) plants designed, manufactured, built and/or commissioned worldwide.

A time lapse video the sun image on a tower target reflected by the Stellio heliostat demonstrates the accuracy with which the sharp image of the sun remains at the

12 m x 12 m target throughout the day.

Time Lapse Video on Vimeo: https://vimeo.com/127245370

Image of the sun on a tower target (© sbp sonne gmbh)

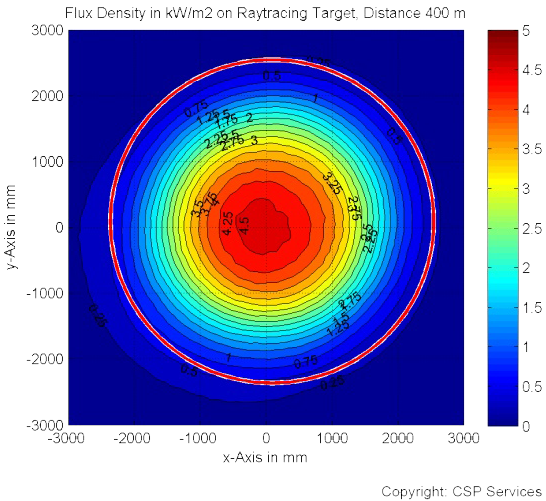

Flux Density in kW/m² on Raytracing Target, Distance 400m (© CSP Services)

Stellio data

| Metric | Performance | Comment |

|---|---|---|

| Reflective Area | 47.45 m² | Net area |

| Diameter | 9 m | For mechanical and safety calculations |

| Clean Mirror Specular Reflectivity | >93 % | Typical value. Final value depends on supplier finally selected, which in turn is result of techno-economic optimization. |

| Service Life | 25 years | Individual components can be easily replaced |

| Focal Length | slant range… slant range + x % | Number of different focal lengths is result of techno-economic optimization, depending on respective heliostat field size and layout. Preliminary number of focal lengths for >80MWel field: 5 |

| Go to Stow wind speed* | 14.8 m/s | 3-sec. gust in 10 m height |

| Maximum allowed wind speed in stow position (‘survival wind speed’)* |

40 m/s | 3-sec. gust in 10 m height. Calculated following the relevant local design code requirements |

| All other environmental loading conditions (seismic, temperature, snow, ice etc.) | (-) | Designed and tested to suit local code requirements or evaluated statistically site specific |

* = current design values to be adjusted to environmental conditions at site

The Stellio Group Partners

Technology development: schlaich bergermann partner,sbp sonne gmbh, Stuttgart, Germany

Manufacturer, Manufacturing line development: Ingemetal Solar, Zaragoza, Spain

Control system development and manufacture: Masermic, Mendaro, Spain

Company profile of schlaich bergermann partner

Schlaich bergermann partner is a structural engineering office with headquarters in Stuttgart, Germany, with offices in Berlin, New York, Shanghai, São Paulo, and Paris.

Solar Energy is a branch of schlaich bergermann partner’s vision for sustainable engineering and sbp sonne gmbh counts with over 30 years of experience in research and development in renewable energy, pioneering technologies and operational frameworks globally. Our strength lies on multi-disciplinary teams formed of engineers and scientists of multiple areas of study, which allows sbp sonne gmbh to develop efficient and cost-effective structural systems otherwise unachievable.

sbp sonne gmbh has developed and built some of the largest solar concentrators and collectors for solar thermal power plants in the world. In 2010 it received the SolarPACES Technology Innovation Award for the Euro Trough Parabolic Trough Collector, and in 2013 it won the SolarPACES Technology Innovation Award for the Ultimate Trough® Parabolic Trough Collector. In 2014, the company was awarded the Stifterverband Hallmark of Excellence, denominated “Innovation through Research.”

Company profile of Ingemetal

Ingemetal is a group of companies establisted in 1981 in Zaragoza (Spain), operating in the construction sector with an international understanding of the business and the technical excellence as its main guideline.

Ingemetal Energías is the group subsidiary operating mainly in the solar sector, with a unique offer in the thermosolar sector, thanks to a vertical integration able to provide globally cost effective turnkey solarfield solutions, ensuring performance guarantees in oustanding terms above the market standards. Its comprehensive offer includes engineering capacities, the supply of the collector steel components from its own plant in Pune (India) and outstanding abilities for the assembly and erection works based on industrialized procedures and own designed, built and calibrated jigs.

Ingemetal Energías has an extensive background in the subject having been involved in the design, supply and/or construction of solar plants worlwide for a total installed capacity above 500 MW with diffferent trough technologies.

For detailed information and images please contact:

Jantje von Reeken

Press Officer

[email protected]

+49 (711) 648 71-87

Schwabstraße 43

D-70197 Stuttgart

www.sbp.de/en

www.masermic.com

www.ingemetalsolar.com